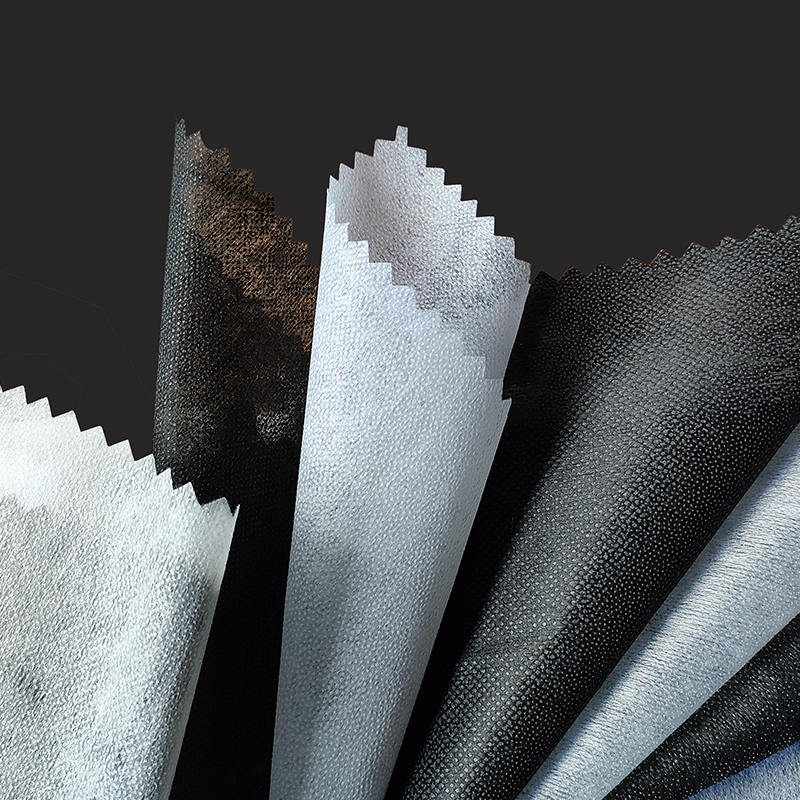

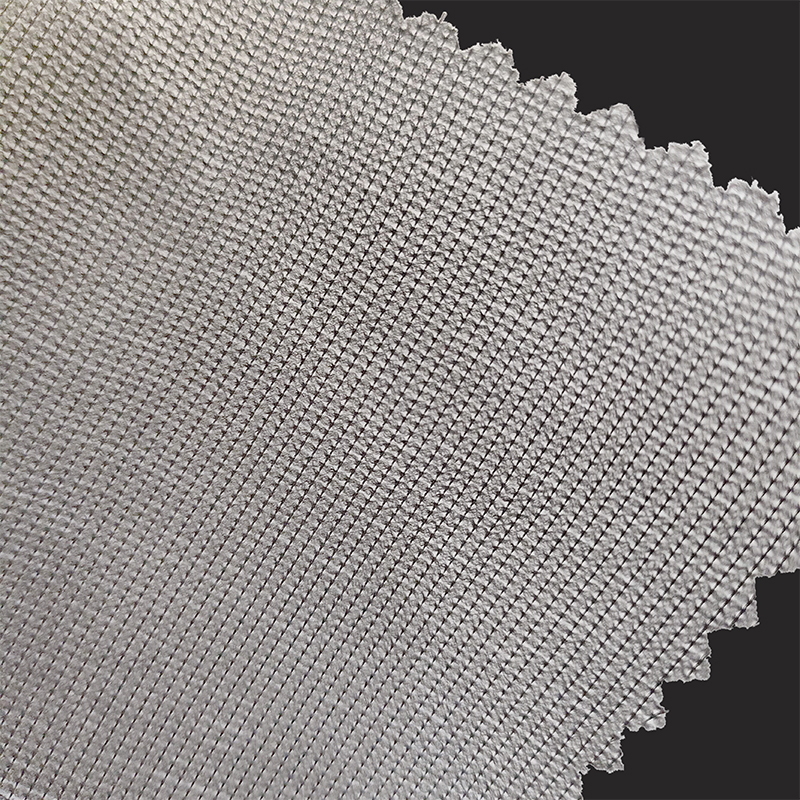

Nonwoven interlining, also known as nonwoven fabric or nonwoven fabric, is a textile that can be manufactured without traditional weaving or knitting processes. It forms cloth by directly gluing, interweaving, or otherwise combining fibers together. The manufacturing process of non-woven interlining usually includes the following steps:

1. Fiber preparation: First, the fibers (can be natural fibers such as cotton, linen, or synthetic fibers such as polyester, polypropylene, etc.) are opened, mixed and cleaned.

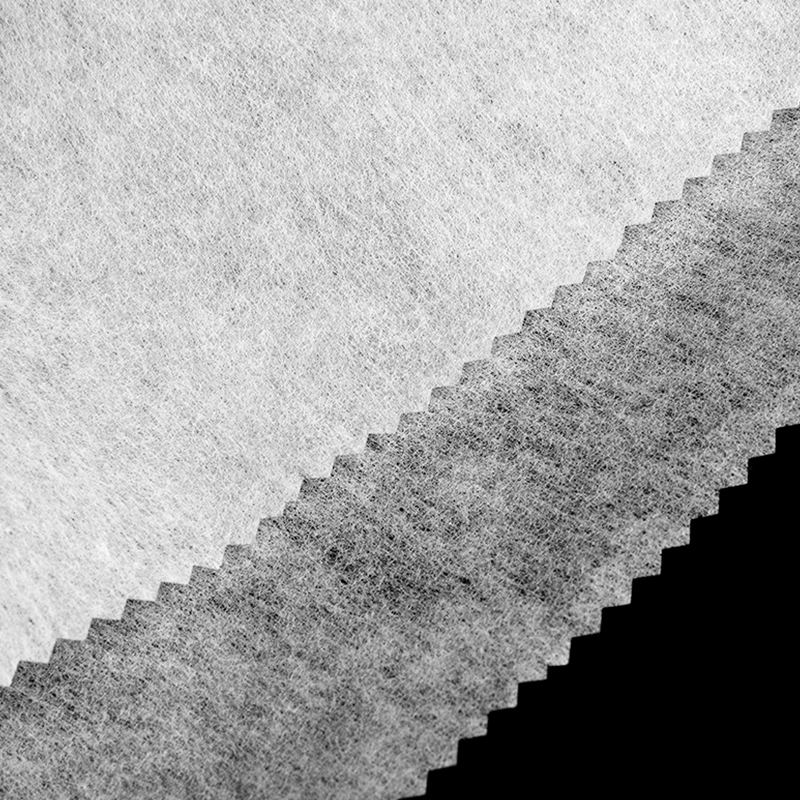

2. Fiber web formation: The prepared fibers are laid into a uniform fiber web through airflow or mechanical means.

3. Reinforcement: The formed fiber web can be reinforced into non-woven fabrics through several methods. Common reinforcement methods include:

- Mechanical reinforcement: the fibers in the fiber web are entangled with each other by needling or hydroentangling.

- Chemical Reinforcement: Using an adhesive to bind the fibers together in the web.

- Heat reinforcement: The fibers are partially melted by hot pressing, thereby bonding them together.

4. Post-processing: The reinforced non-woven fabric may undergo some post-processing processes, such as heat setting, cutting, winding, etc., to meet specific application requirements.

5. Cutting and packaging: Finally, the non-woven fabric is cut into the required size and shape, then packaged and ready for shipment.

Non-woven interlinings are popular because of their simple production process, low cost and wide range of uses. They can be used for a variety of purposes, including but not limited to:

- Garment linings: used for linings of shirts, jackets, skirts, etc.

- Medical and health care: such as surgical gowns, masks, medical caps, etc.

- Household items: such as bed sheets, pillowcases, tablecloths, etc.

- Industrial applications: such as filter materials, insulation materials, reinforcement materials, etc.

The properties of nonwovens can be adjusted according to the fiber type used, the structure of the fiber web and the reinforcement method to meet different application requirements.

English

English Español

Español Türk

Türk