How exactly is Thermobond Nonwoven Interlining made using thermal bonding technology?

In the world of garment accessories, Thermobond Nonwoven Interlining plays a crucial role in enhancing the quality and durability of garments. But have you ever wondered how this remarkable product is made through heat bonding technology?

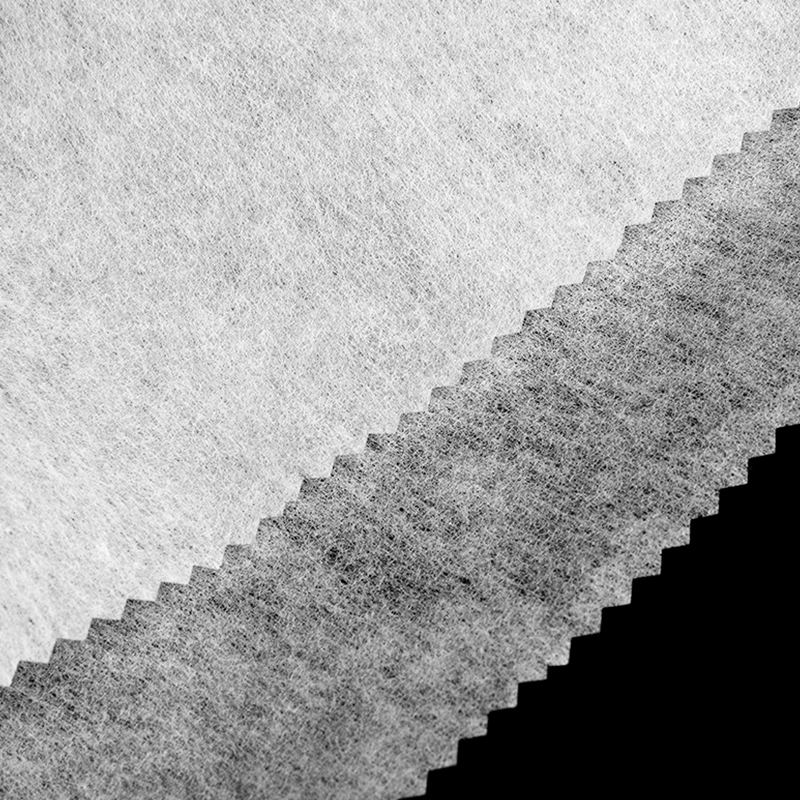

The production of Thermobond Nonwoven Interlining begins with the careful selection of raw materials. Rugao Jilin Garment Accessories Co., Ltd. is committed to sourcing high-quality fibers that meet strict quality standards. These fibers are then processed and prepared for the next stage of production.

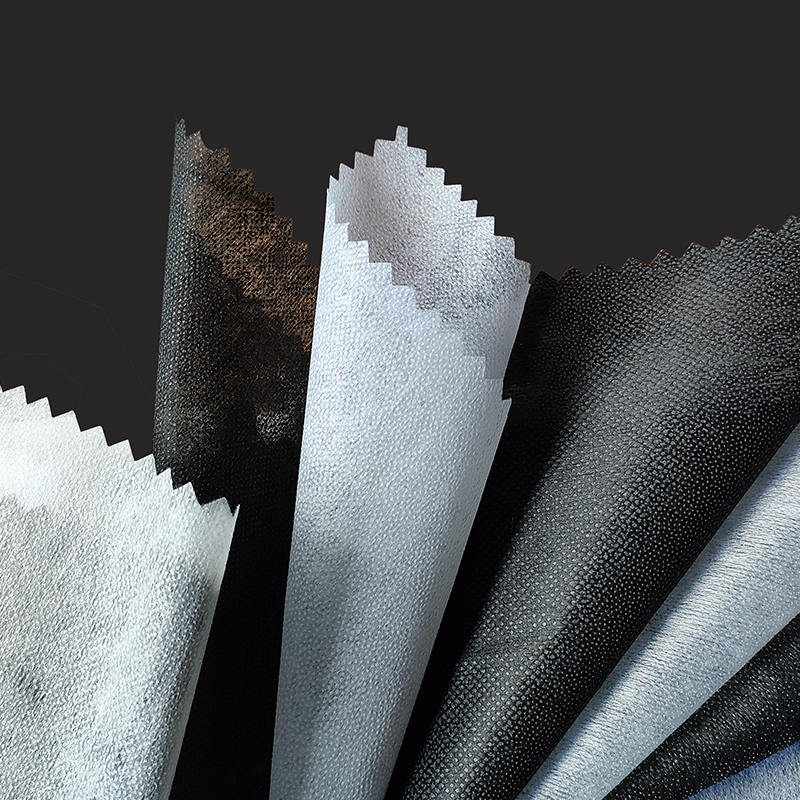

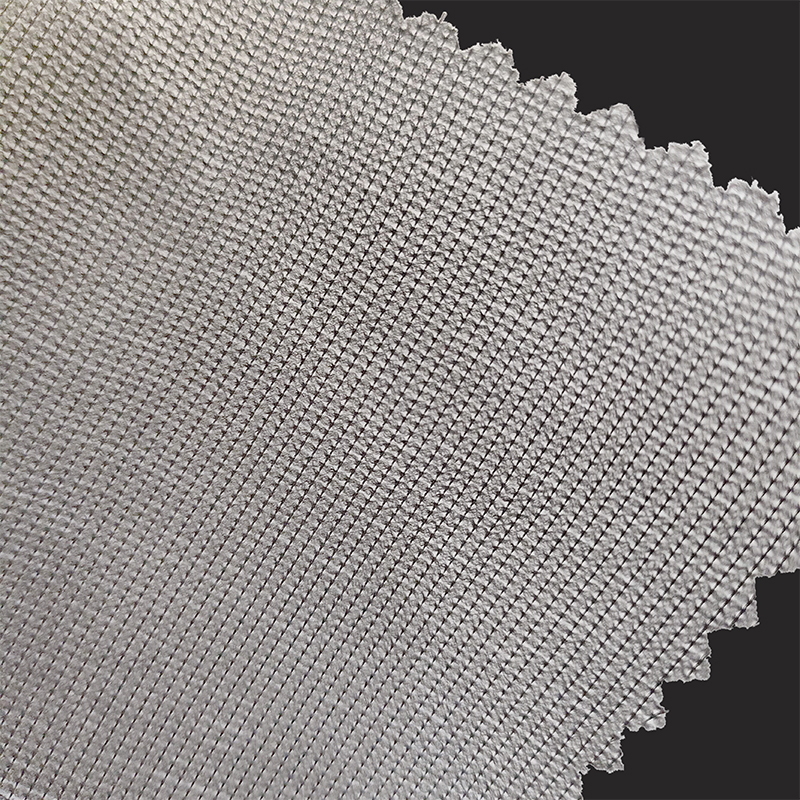

The heart of the manufacturing process lies in the heat bonding technology. Using advanced double-dot coating production lines, the company applies heat and pressure to bond the nonwoven fibers together. This process is carefully controlled to ensure that the interlining has the desired strength, flexibility, and adhesion properties.

During the heat bonding process, the temperature and pressure are precisely adjusted to achieve the optimal bonding effect. The heat causes the fibers to melt slightly and fuse together, creating a strong and stable structure. At the same time, the double-dot coating technique ensures that the bonding is evenly distributed, providing consistent performance throughout the interlining.

The scientific production process employed by Rugao Jilin Garment Accessories Co., Ltd. also includes quality control measures at every stage. Skilled technicians monitor the production line closely, checking for any defects or irregularities. Only products that meet the company's stringent quality standards are allowed to move on to the next stage.

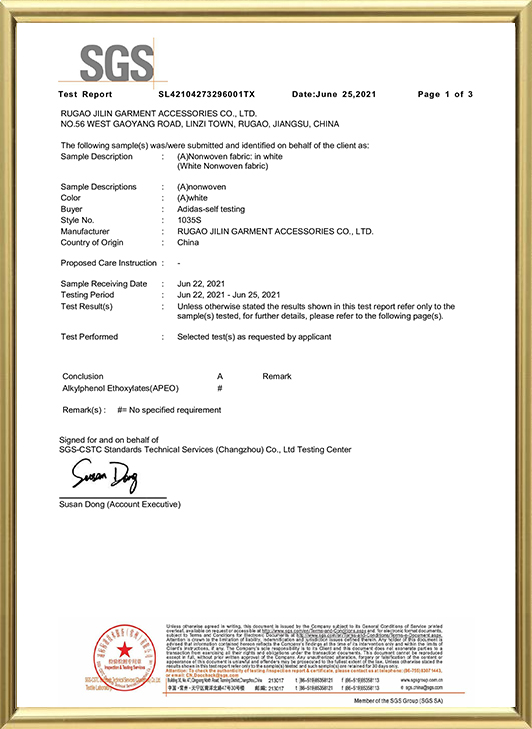

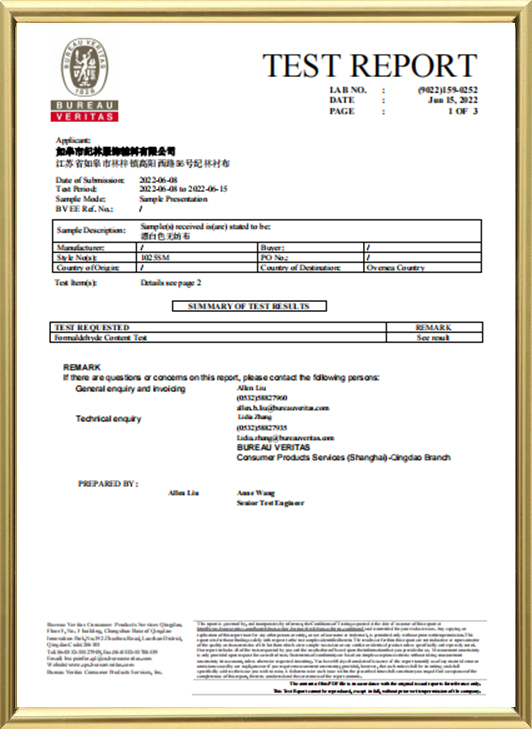

Once the Thermobond Nonwoven Interlining is produced, it undergoes further testing and certification. The company's products have all passed OEKo-TEX 100 and TQP certification, ensuring that they are free from harmful substances and meet international environmental and quality standards.

Thanks to its advanced production technology and commitment to quality, Rugao Jilin Garment Accessories Co., Ltd.'s Thermobond Nonwoven Interlining is exported to more than ten countries and regions such as Europe, America, Korea, and Southeast Asia. It has been recognized and trusted by many famous garment brands worldwide, earning a reputation for excellence.

The heat bonding technology used by Rugao Jilin Garment Accessories Co., Ltd. to produce Thermobond Nonwoven Interlining is a complex and sophisticated process that requires precision and expertise. By combining high-quality raw materials with advanced production techniques and strict quality control, the company is able to create a product that meets the needs of garment manufacturers around the world. Whether it's for enhancing the structure of a jacket or adding stability to a shirt collar, Thermobond Nonwoven Interlining is an essential component in the world of fashion.

English

English Español

Español Türk

Türk