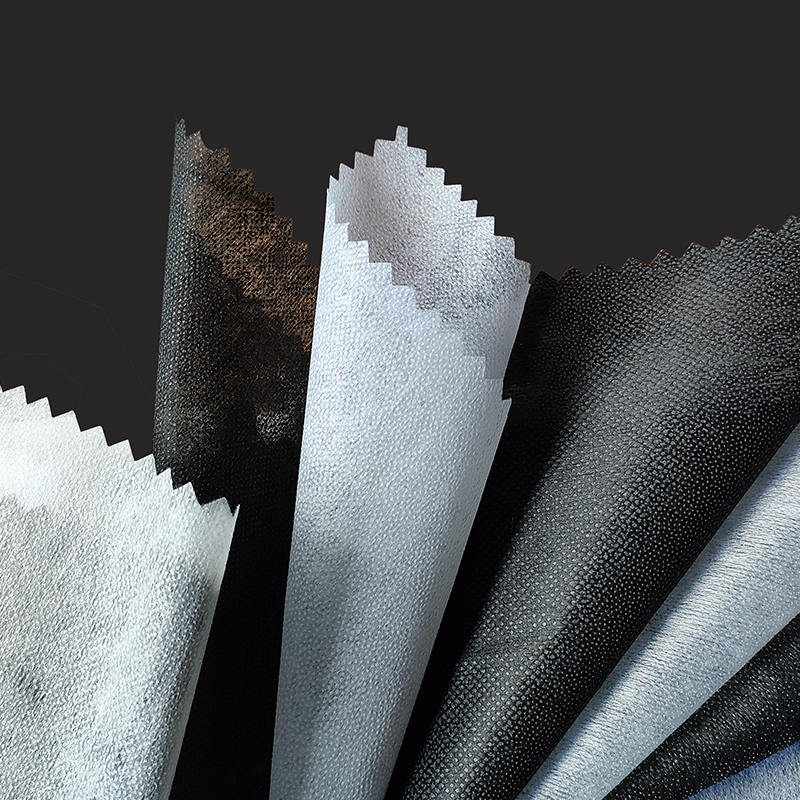

The performance of chemically bonded nonwoven interlinings may indeed change after long-term exposure to high temperature. Specifically, this change mainly depends on multiple factors such as the material composition, production process, use of additives, and exposure temperature and time of the nonwoven interlining.

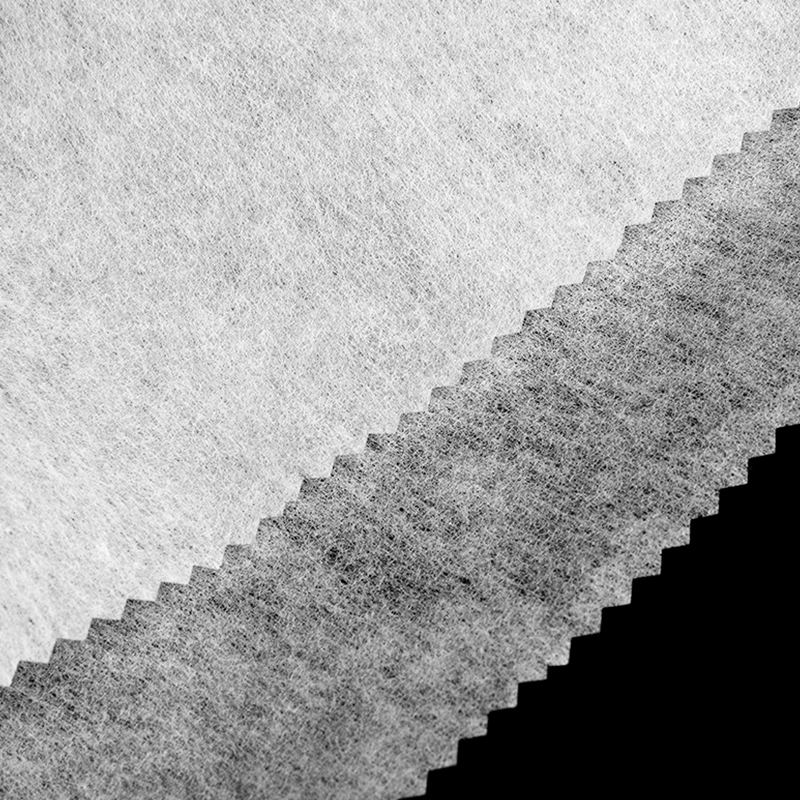

First of all, from the perspective of material composition, chemically bonded nonwoven interlinings generally use polyester as the main raw material. Although this material has a certain stability in a high temperature environment, long-term exposure to high temperature may still cause it to undergo thermal aging. Polyester may undergo reactions such as molecular chain breakage and rearrangement at high temperatures, resulting in a gradual decrease in the mechanical properties of the material, such as tensile strength and elongation at break.

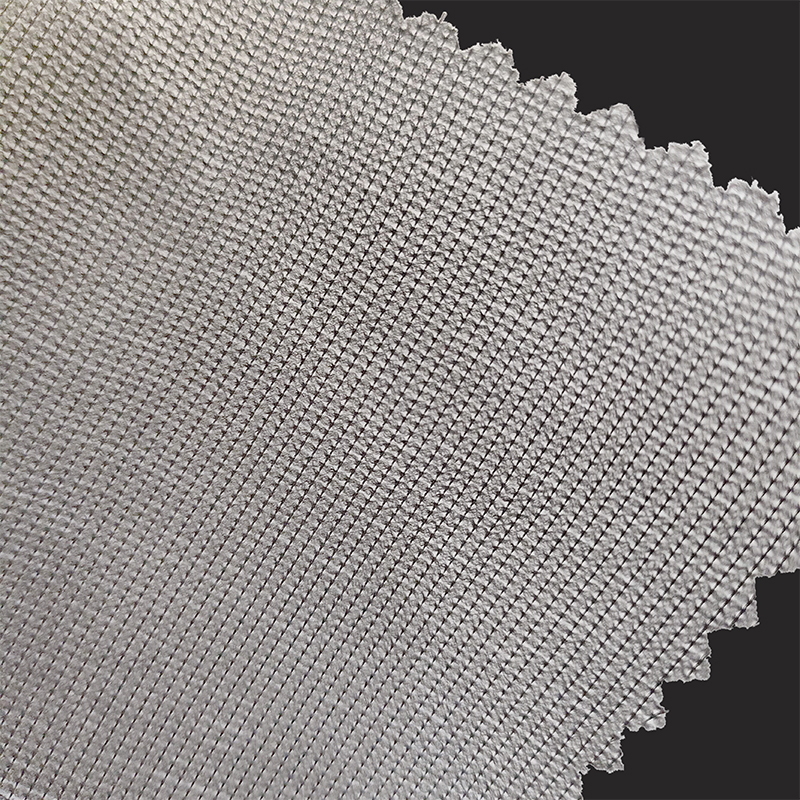

Secondly, adhesives are used in the production process of nonwoven interlinings to increase the bonding force between fibers. The aging resistance and chemical stability of these adhesives have an important influence on the high temperature resistance of nonwoven interlinings. If the adhesive is easily degraded at high temperatures, the overall structure of the nonwoven interlining may become loose and the strength may decrease, thereby affecting its performance.

In addition, various functional additives may be added to the nonwoven interlining, such as UV inhibitors and flame retardants. The stability of these additives at high temperatures will also affect the overall performance of the nonwoven interlining. If the additive fails or reacts adversely at high temperatures, it may cause color changes, odor or other adverse consequences of the nonwoven interlining.

Specific to this product - chemically bonded nonwoven interlining, it has been specially treated to withstand high-temperature combing up to 260°C. This shows that it is feasible for the product to withstand high temperatures for a short period of time and may have certain high-temperature stability. However, long-term high-temperature exposure remains a challenge because even if the material itself can withstand high temperatures, long-term thermal aging may still cause its performance to gradually decline.

Therefore, when using chemically bonded nonwoven interlinings, long-term exposure to high temperatures should be avoided as much as possible. If it is necessary to use it in a high-temperature environment, it is recommended to conduct sufficient testing to evaluate its high-temperature resistance and take corresponding protective measures according to actual conditions to ensure its stable performance.

The performance of chemically bonded nonwoven interlinings may change after long-term exposure to high temperatures, and the specific degree of change depends on the combined effect of multiple factors. In practical applications, it should be selected and used according to specific needs and conditions.

English

English Español

Español Türk

Türk