1. Basic functions and roles of Interlining materials

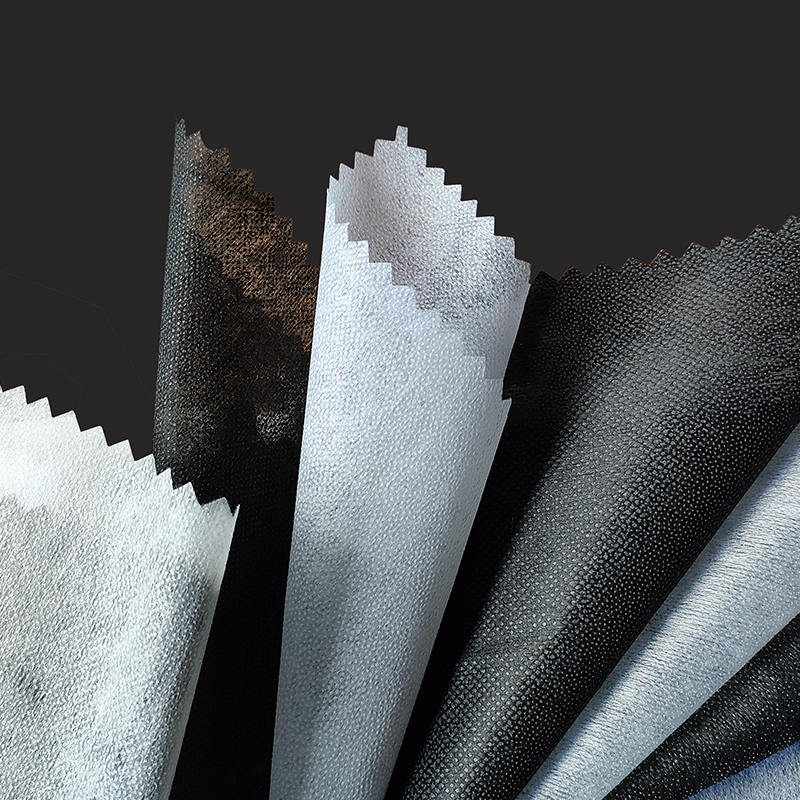

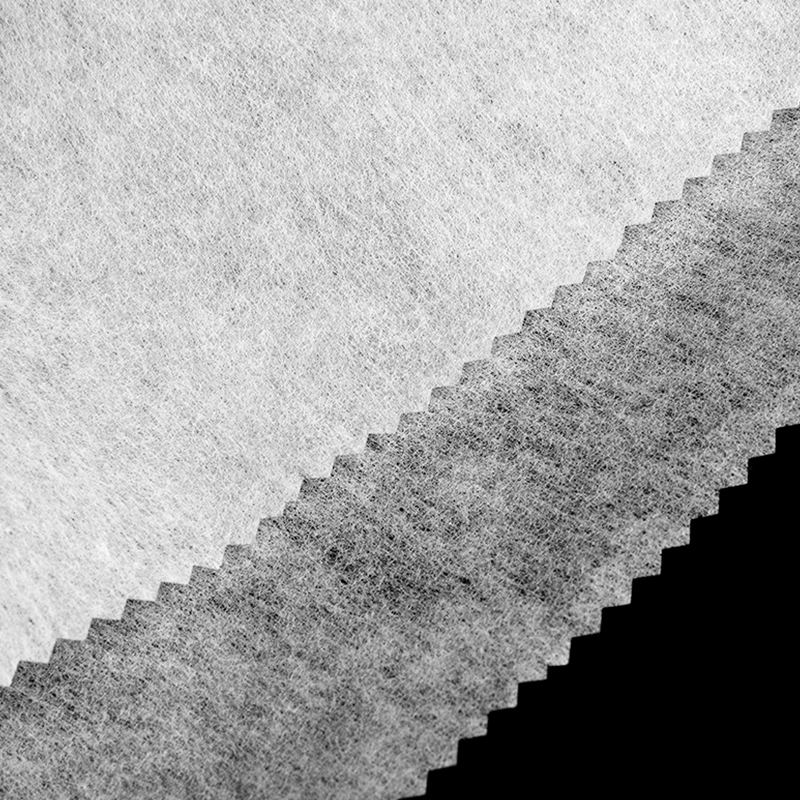

Interlining is an auxiliary material used in clothing production. It mainly plays the role of strengthening clothing structure, increasing support, maintaining shape and extending service life. It is usually located between the outer fabric and the lining, not only providing shape support for the clothing, but also has the functions of strengthening and protection. For outdoor clothing, the choice of Interlining is particularly important because it needs to ensure the durability, waterproofness and wind resistance of the clothing while providing comfort.

2. Key factors to improve waterproof performance

When choosing Interlining materials for outdoor clothing, there are several key factors to consider to ensure that the material can provide reliable waterproof performance in various harsh environmental conditions:

Waterproof coating of materials

Many Interlining materials are added with a special waterproof coating such as polyurethane (PU) or polytetrafluoroethylene (PTFE) during manufacturing. These coatings can effectively prevent moisture penetration while allowing water vapor to be discharged from the inside, ensuring that the clothing is breathable and dry. This is similar to the design concept of outdoor camping fans. Lightweight and durable materials can ensure that the product will not be affected by moisture when used in a humid environment. Its service life and performance will not be affected by moisture.

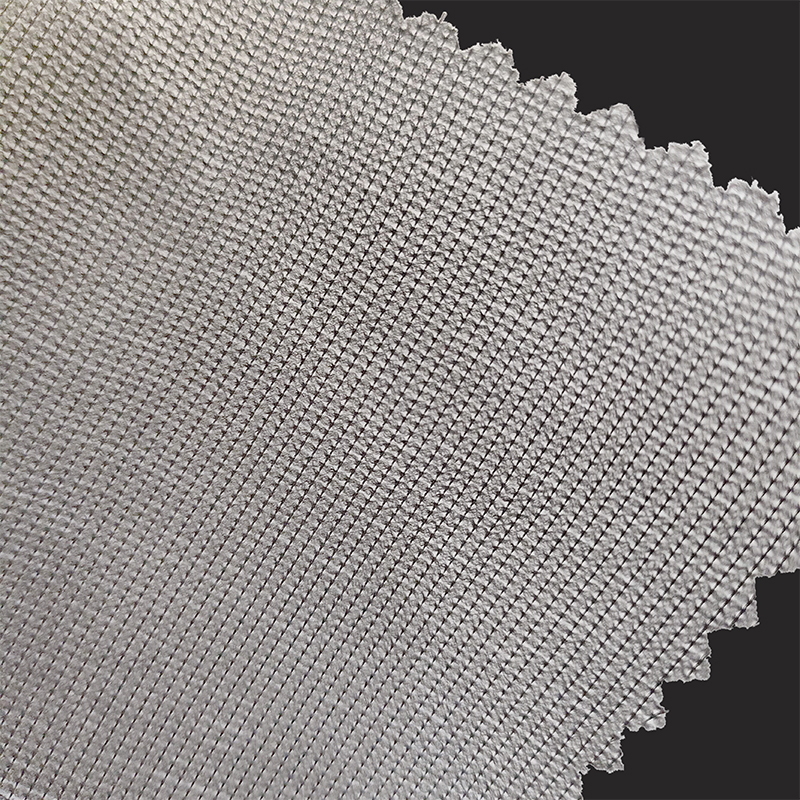

Wear resistance and strength

Outdoor environments are often accompanied by frequent friction, pulling and impact. The strength and wear resistance of Interlining materials must meet certain standards to ensure that clothing will not wear out prematurely during long-term use. For example, outdoor equipment such as car air pumps and portable car heating fans often use highly wear-resistant metal materials to ensure that the product maintains stable performance in extreme environments. Similarly, the Interlining of outdoor clothing must also have high strength and wear resistance to cope with harsh outdoor conditions.

Windproof and breathable

In addition to improving waterproof performance, Interlining materials must also have good windproof performance to ensure that clothing can withstand strong winds and maintain internal warmth and comfort. In addition, the breathability of the material is equally important. During outdoor activities, the human body is prone to sweating, and materials with poor breathability will prevent moisture from being discharged, which in turn affects the wearing experience. Similar to the temperature control technology in thermoelectric coolers, the breathability of Interlining materials must be balanced with waterproof performance to ensure comfort and practicality

3. How to choose the right Interlining material

Choose the type of material according to the purpose

Different outdoor activities require different types of Interlining materials. For example, mountaineering clothing requires lighter and more breathable materials, while ski clothing needs to pay more attention to warmth retention and waterproofness. Therefore, when choosing, you should choose the appropriate Interlining material according to the specific purpose.

Pay attention to the technical parameters of the material

When choosing Interlining, you should pay attention to its technical parameters such as waterproof level (such as IP level), breathability index, strength index, etc. These indicators can help designers and manufacturers better judge the applicability of the material and ensure that the clothing can provide the best performance under different environmental conditions.

Combined with modern technology

The development of modern technology has brought more innovative possibilities to Interlining materials, such as nano-coating technology and smart fabrics. These technologies can significantly improve the functionality of the material, making it lighter and thinner while still having excellent waterproof, breathable and durable properties.

English

English Español

Español Türk

Türk