1. The key role of Interlining materials

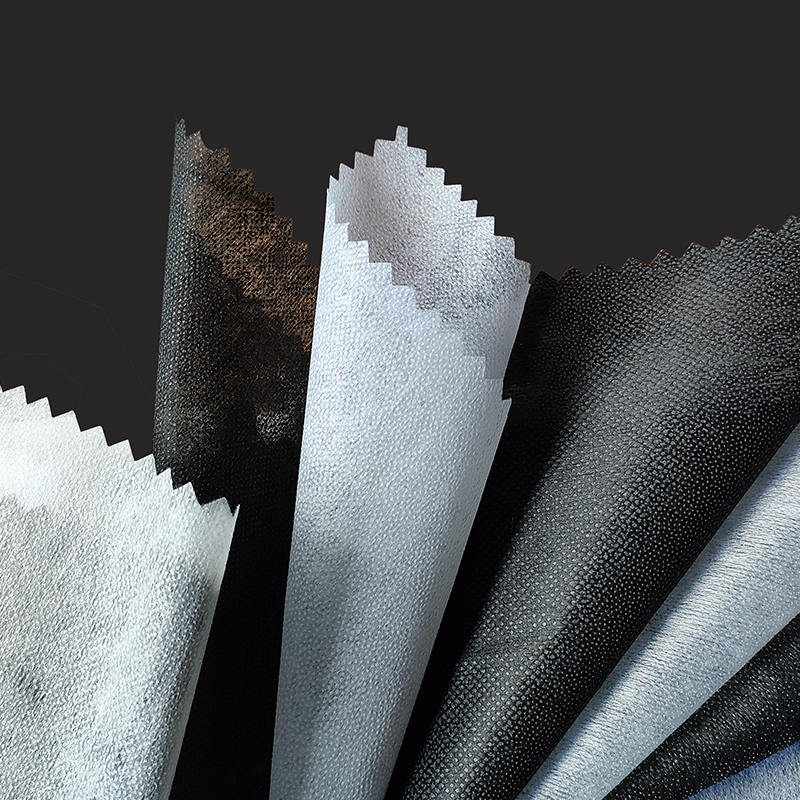

As an auxiliary material in clothing and equipment, Interlining is usually located between the outer fabric and the lining, which plays a role in strengthening the structure, supporting the shape, maintaining stability and extending the service life. In the application of outdoor products, Interlining must not only meet the basic structural support requirements, but also take into account special properties such as waterproof and durable. For outdoor clothing and equipment, the correct selection of Interlining materials is one of the core steps to improve waterproof performance.

2. Main factors to improve waterproof performance

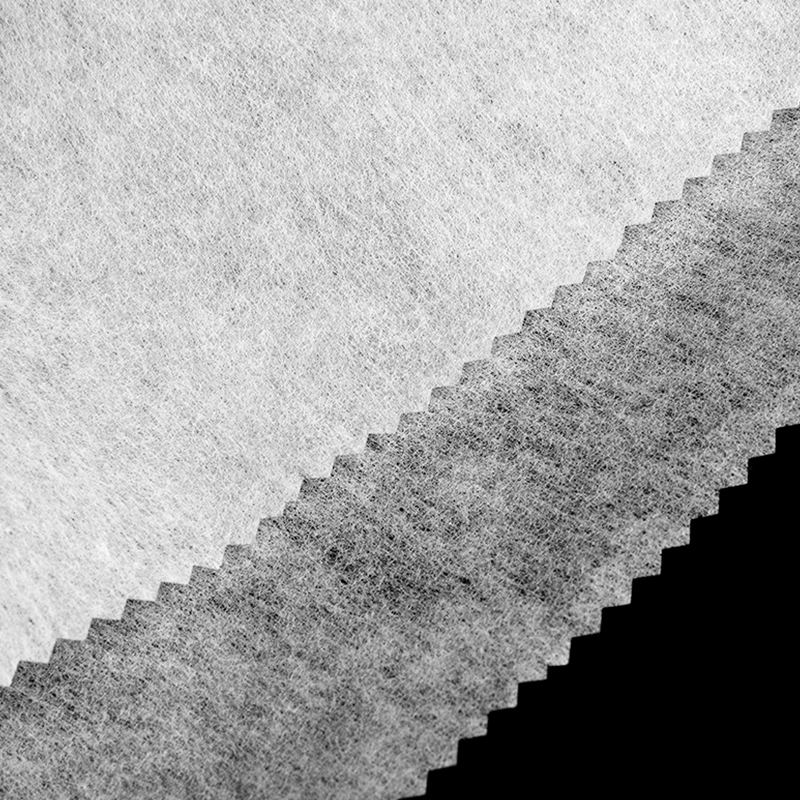

1. Waterproof treatment of materials

By selecting Interlining materials with waterproof coatings, water penetration can be effectively prevented while maintaining the breathability of clothing or equipment. Common waterproof coatings include polyurethane (PU) coatings and polytetrafluoroethylene (PTFE) coatings, which can block external moisture and allow water vapor to be discharged from the inside, ensuring that users stay dry and comfortable when wearing or using equipment.

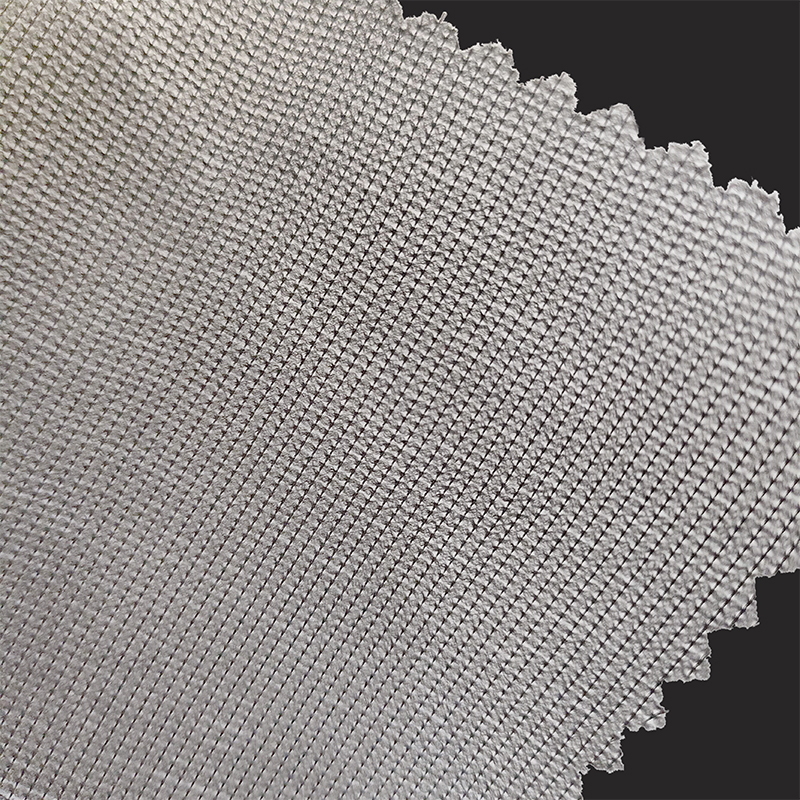

2. Wear resistance and durability

Outdoor environments are often accompanied by physical impact and wear. Interlining materials must have sufficient wear resistance and durability to effectively protect the core structure of clothing or equipment. For example, car air pumps usually need to be used on rough ground. If wear-resistant Interlining materials are used, it can not only extend the service life of the equipment, but also maintain its structural integrity while being waterproof.

3. Windproof and thermal insulation performance

In outdoor environments, Interlining must not only provide waterproof functions, but also have windproof and thermal insulation properties. For some outdoor clothing that needs to be in a cold environment for a long time, such as mountaineering clothes or ski clothes, Interlining materials should have excellent thermal insulation effects and effectively block the invasion of cold wind.

III. Tips for choosing suitable Interlining materials

1. Select materials according to product use

Different outdoor equipment and clothing have different requirements for Interlining materials. For outdoor clothing that requires extremely strong waterproofness, materials with waterproof coating and good breathability should be selected; for outdoor equipment such as car air pumps, durability and impact resistance are the key. In addition, lightness is also a factor that some outdoor equipment needs to consider. Choosing lightweight Interlining materials can reduce product weight while maintaining functionality and improve the user experience.

2. Pay attention to material technical parameters

When choosing Interlining materials, it is very important to pay attention to their technical parameters, such as waterproof grade, air permeability coefficient, strength and other indicators. Different product usage scenarios require different technical requirements. When choosing, the appropriate Interlining material should be matched according to the actual needs of the product design to ensure that the waterproof, windproof and durability achieve the expected effect.

3. Use modern technology to improve performance

Today, the application of nano-coating technology and smart fabrics provides more innovative options for Interlining materials. These new materials are not only lightweight, but also can significantly improve waterproof and durable performance, making the overall performance of outdoor equipment and clothing better.

English

English Español

Español Türk

Türk