1. Strength and tear resistance

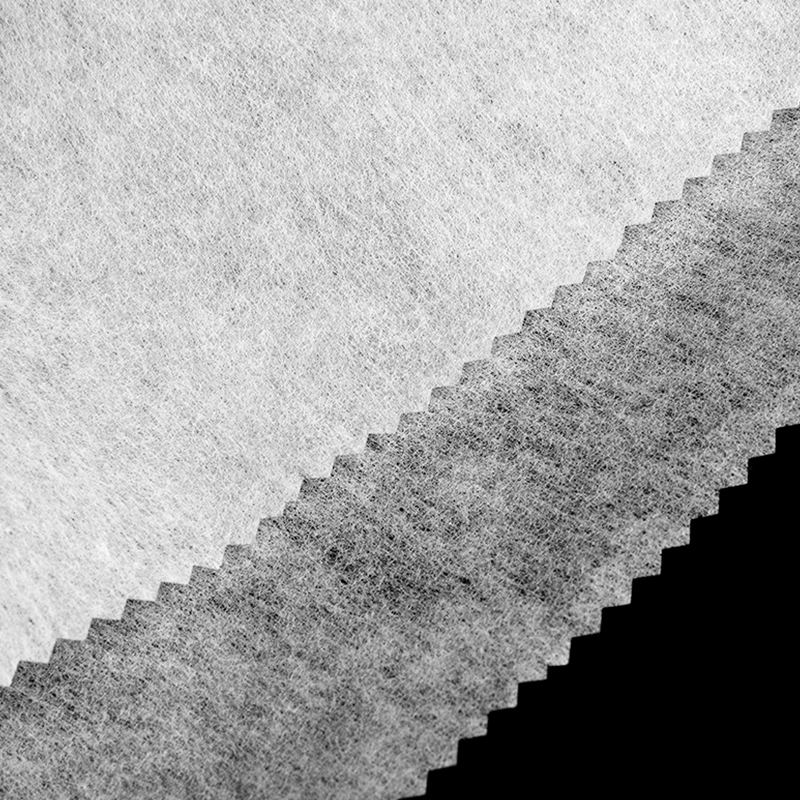

Nonwoven fabrics generally show higher advantages in strength and tear resistance than traditional textile fabrics. Traditional fabrics form a fabric structure by interweaving yarns. Although they have certain strength, they are easily torn by external forces because of the large pores in their structure. In contrast, nonwoven fabrics usually adopt a fiber mesh structure, especially nonwoven fabrics consolidated by processes such as hot pressing and mechanical needle punching, which have higher tensile strength and tear resistance.

In addition, polypropylene nonwoven fabrics also show good durability in tear resistance and stretch resistance due to their excellent chemical stability and low density. This allows it to maintain a longer service life in disposable consumer products (such as medical dressings, sanitary napkins, etc.).

2. Chemical resistance and corrosion resistance

Nonwoven fabrics are generally more chemically resistant than traditional textile fabrics, especially when using synthetic fibers such as polypropylene and polyester, which have strong acid resistance, alkali resistance, oil resistance, solvent resistance and other characteristics. For example, polypropylene non-woven fabrics are often used in medical and environmental protection applications, such as disposable protective equipment, filter materials, etc., due to their excellent chemical resistance. In some highly corrosive environments, polyester non-woven fabrics can maintain a longer service life due to their high temperature resistance, oxidation resistance and corrosion resistance.

In contrast, traditional textile fabrics are often easily damaged when facing chemical substances. For example, natural fiber fabrics such as cotton and silk will age, corrode or fade under the action of acids, alkalis or organic solvents. Therefore, the advantages of non-woven fabrics in chemical resistance make them more widely used in industrial, medical and chemical fields, especially in applications such as filtration and storage, where they can play a long and stable role.

3. Anti-ultraviolet and high temperature resistance Non-woven fabrics, especially those made of polypropylene and polyester fibers, usually have good anti-ultraviolet and high temperature resistance. Polypropylene non-woven fabrics have strong anti-ultraviolet function and can maintain stable physical properties under long-term exposure to sunlight.

Traditional natural textile fabrics such as cotton and linen, although breathable, are often susceptible to damage from UV rays, causing the material to become brittle, discolored, or lose strength. In addition, traditional textiles are susceptible to thermal deformation or melting in high temperature environments, especially without special treatment. In contrast, non-woven fabrics have better heat resistance after being treated with a thermal consolidation process, making them suitable for applications in high temperature environments, such as filter materials, industrial protection, and automotive interiors.

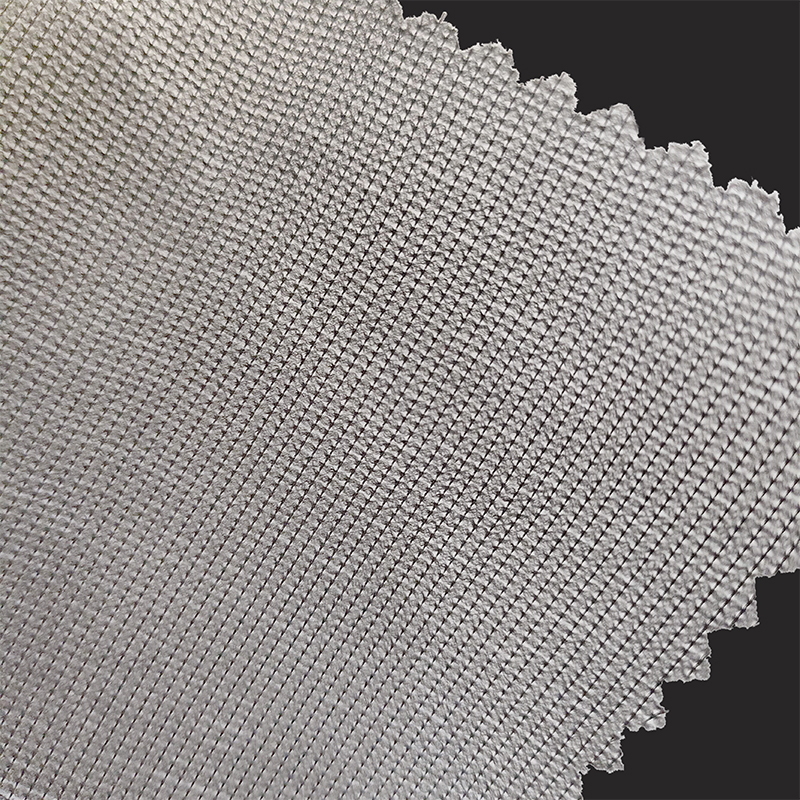

4. Water resistance and breathability

Non-woven fabrics are generally better in water resistance and breathability than traditional fabrics, especially polypropylene non-woven fabrics. Polypropylene non-woven fabrics have good breathability and moisture absorption and moisture removal properties due to their loose fiber mesh structure and low density, which makes them widely used in sanitary products, medical protection, and water filtration. Compared with traditional textile fabrics, polypropylene non-woven fabrics have more outstanding water resistance and can still maintain their structure and performance in a humid environment.

On the other hand, traditional woven fabrics such as cotton fabrics, although they perform well in terms of breathability, are easy to absorb water in a humid environment, causing the fabric to become heavier or lose its original strength. Nonwoven fabrics, especially those treated with water-based coatings, can provide excellent waterproof properties and are widely used in packaging, protective films, and isolation materials.

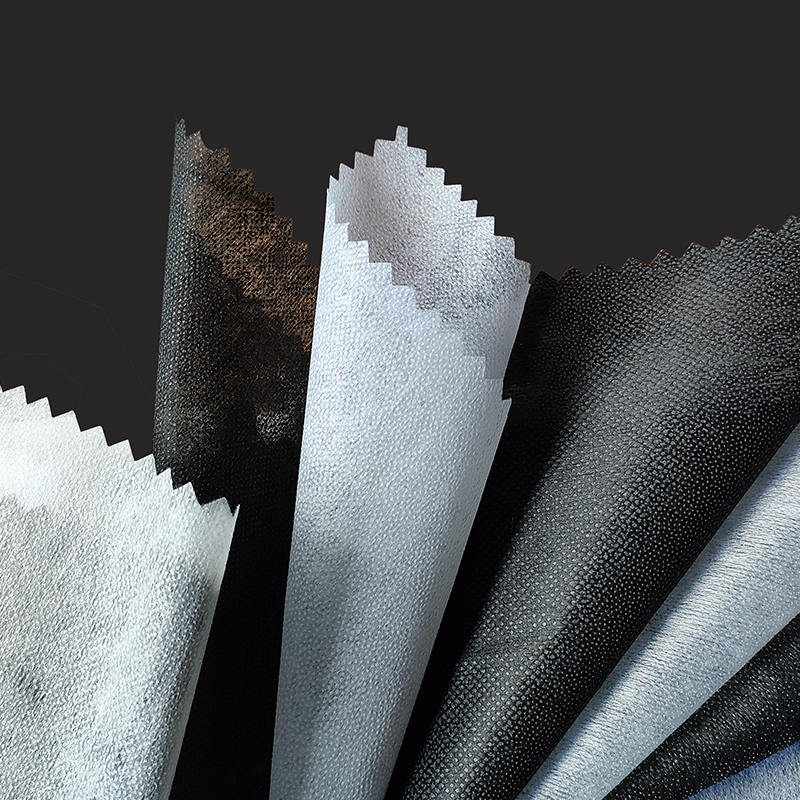

5. Customizability and functionality

Another major durability advantage of nonwoven fabrics is their customizability. The production process of nonwoven fabrics can be adjusted according to different application requirements, such as by adjusting the density, thickness, structure, surface treatment, etc. of the fiber to customize nonwoven products with different functions. The combination of fibers such as polyester, polypropylene, and vinylon enables nonwoven fabrics to have specific functionality, such as antibacterial, antistatic, and flame retardant.

In contrast, traditional woven fabrics usually lack this high degree of customizability, have a relatively simple functionality, and are difficult to meet the complex material requirements of specific industries. Therefore, nonwoven fabrics have unique advantages in meeting special needs, especially in the field of functional materials that require high added value, such as medical dressings, disposable protective clothing, etc.

English

English Español

Español Türk

Türk