Reasons for fabric deformation during embroidery

During the embroidery process, the fabric may experience multiple needle punches, stretching and striking, especially when embroidering complex patterns or high-density embroidery. Each stitch may cause the shape of the fabric to change, especially for some weaker or more elastic fabrics, which may cause stretching, wrinkling or skewing. After the embroidery is completed, the fabric may become uneven due to the loss of its original tension, affecting the overall effect and even damaging the beauty of the embroidery design. The use of Embroidery Stabilizer Backing can just avoid these problems and ensure that the embroidery design always remains perfect.

The role of Embroidery Stabilizer Backing

As a support material specially designed for embroidery, Embroidery Stabilizer Backing can effectively prevent the fabric from deforming after embroidery by providing additional support for the fabric. Specifically, Embroidery Stabilizer Backing helps the fabric to remain flat and stable in the following ways:

Provide support and stability: During the embroidery process, the needle repeatedly punctures the fabric, which can easily cause the fabric to loosen or stretch, especially on fabrics with strong elasticity. Embroidery stabilizing backing provides strong support for the fabric so that it will not move or loosen due to the traction of the needle and thread during embroidery.

Prevent fabric stretching and twisting: Embroidery stabilizing backing can maintain the tension of the fabric during embroidery, preventing the fabric from stretching unnecessarily when pressure is applied, especially for elastic fabrics and fabrics. For example, fabrics such as sportswear and stretch cotton are easily deformed by the needle action during the embroidery process. By using stabilizing backing, the stretch of the fabric can be effectively controlled to maintain the clarity and symmetry of the design.

Avoid wrinkles and folds: Due to the frequent movement of embroidery stitches, the fabric may have local folds or wrinkles in the embroidery area, affecting the overall effect. Embroidery stabilizing backing increases the stiffness of the fabric, keeping it flat during the embroidery process, thereby avoiding the formation of wrinkles caused by excessive folding or shrinking.

Maintain the shape of the fabric after embroidery: After embroidery is completed, many fabrics may become soft or lose elasticity due to repeated needle action, causing the originally flat design to deform. The stable backing can form a fixed support structure during the embroidery process, ensuring that the embroidery pattern will not be disturbed by external forces after completion, maintaining the accuracy and integrity of the design.

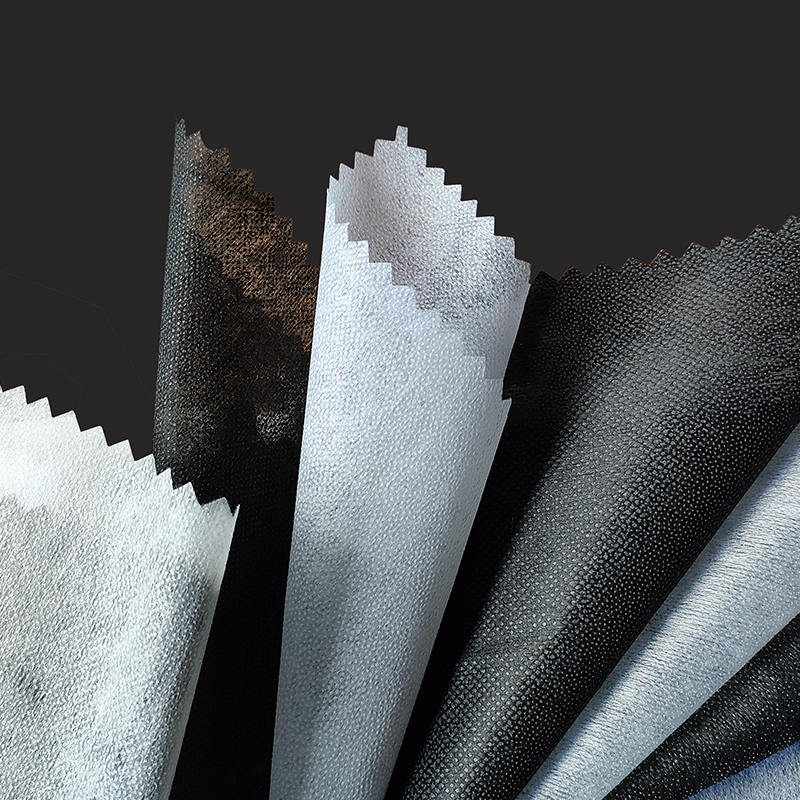

Characteristics of water-soluble and polyester stable backings

Embroidery stable backings are mainly divided into water-soluble backings, polyester backings, and viscose backings according to different needs and fabric characteristics. Different types of backings are suitable for different fabrics and embroidery needs. The following is an introduction to two common backings:

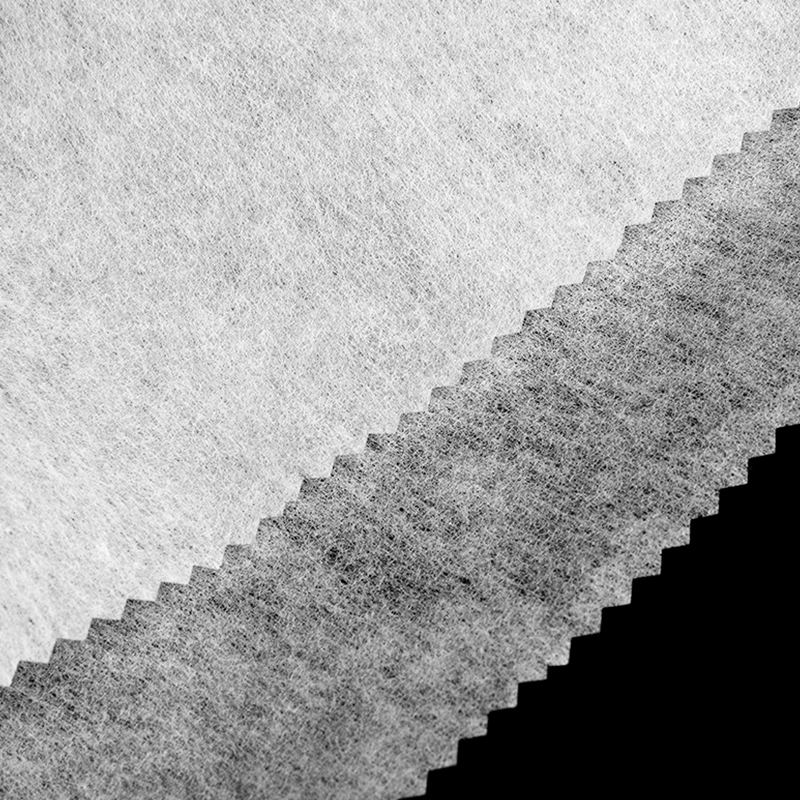

Water-soluble backing: Water-soluble backing can be completely dissolved during washing and is suitable for embroidery projects that require complete removal of the backing, such as fine embroidery or high-end fabrics. Since it does not leave any residue after dissolving in water, water-soluble backing is suitable for high-end fabrics such as silk and lace, which can ensure the cleanliness and tidiness of the fabric surface and avoid the adverse effects that may be caused by traditional backing materials.

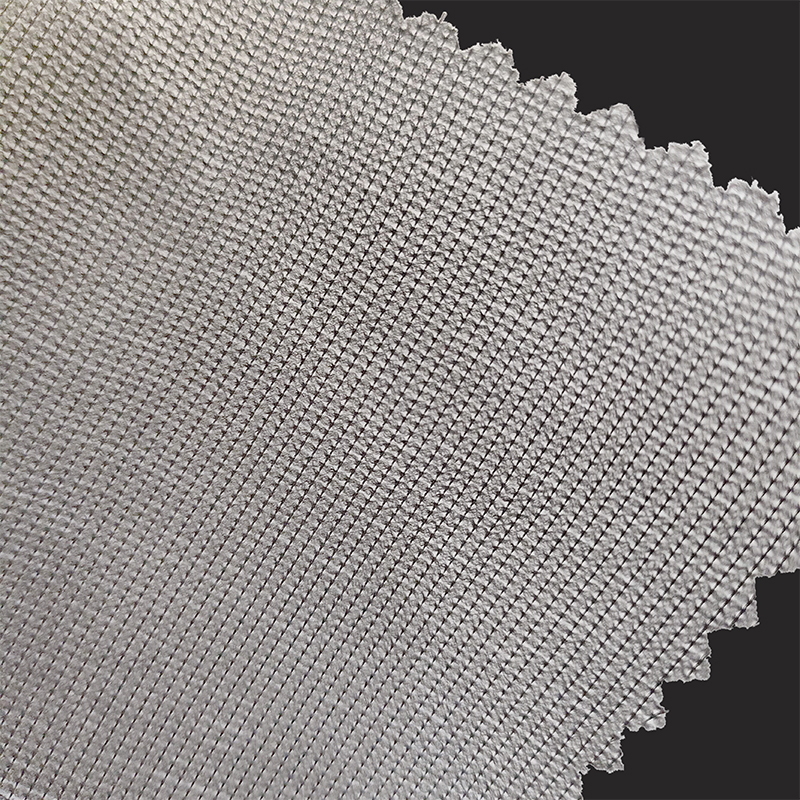

Polyester backing: Polyester backing is stronger than water-soluble backing and is suitable for fabrics that need to be supported for a longer time, such as denim, canvas, etc. This backing can effectively prevent the fabric from deforming and wrinkling during the embroidery process, and it also has high durability.

Tips for using embroidery stabilizing backing

When using embroidery stabilizing backing, it is important to choose the right type and thickness. For thinner or more elastic fabrics, it is recommended to use a soft water-soluble backing or viscose backing, which can provide sufficient support without affecting the flexibility of the fabric. For thicker or more solid fabrics, you can choose a polyester backing to ensure that the fabric remains flat during the embroidery process and avoid excessive stretching or twisting.

English

English Español

Español Türk

Türk