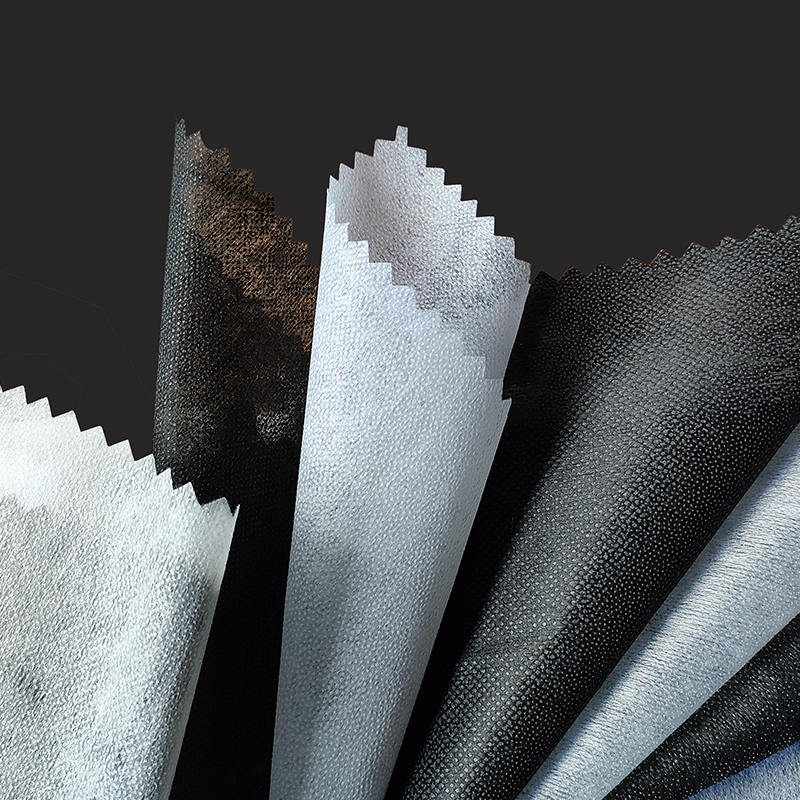

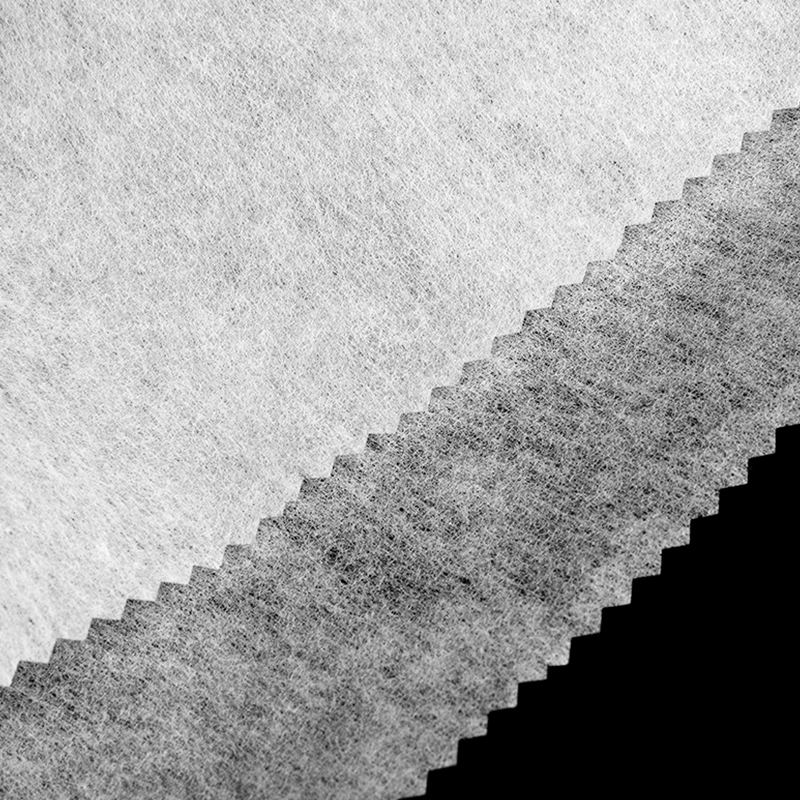

Both Adhesive Film is a mesh hot melt adhesive film with a physical form similar to non-woven fabrics. It is widely used in textiles, leather, foam and other fields. With its environmental protection, breathability and fire resistance, this film has become an important material in many industries.

1. Material composition

The main components of double-sided adhesive films usually include polyamide (PA), polyether ester (PES), ethylene-vinyl acetate copolymer (EVA) and thermoplastic polyurethane (TPU). These materials not only provide excellent adhesion, but also meet the performance requirements of different applications.

2. Performance characteristics

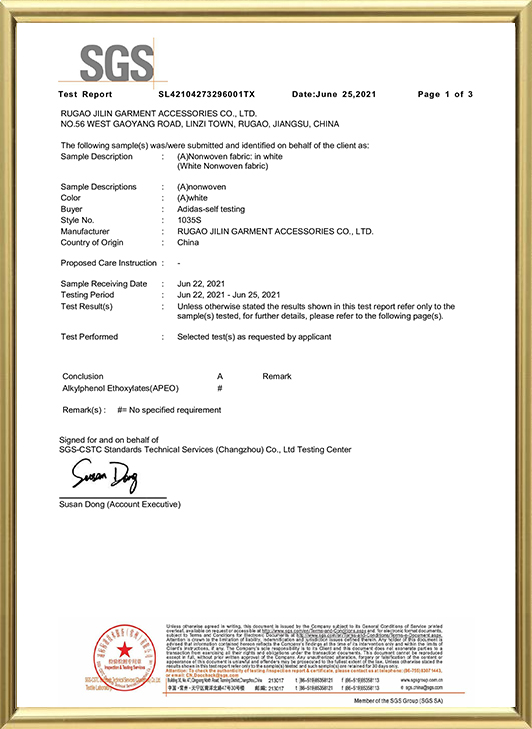

Environmental protection: Double-sided adhesive films are usually produced with non-toxic materials, meet environmental protection standards, and are suitable for products that require environmental certification, such as children's products and medical devices.

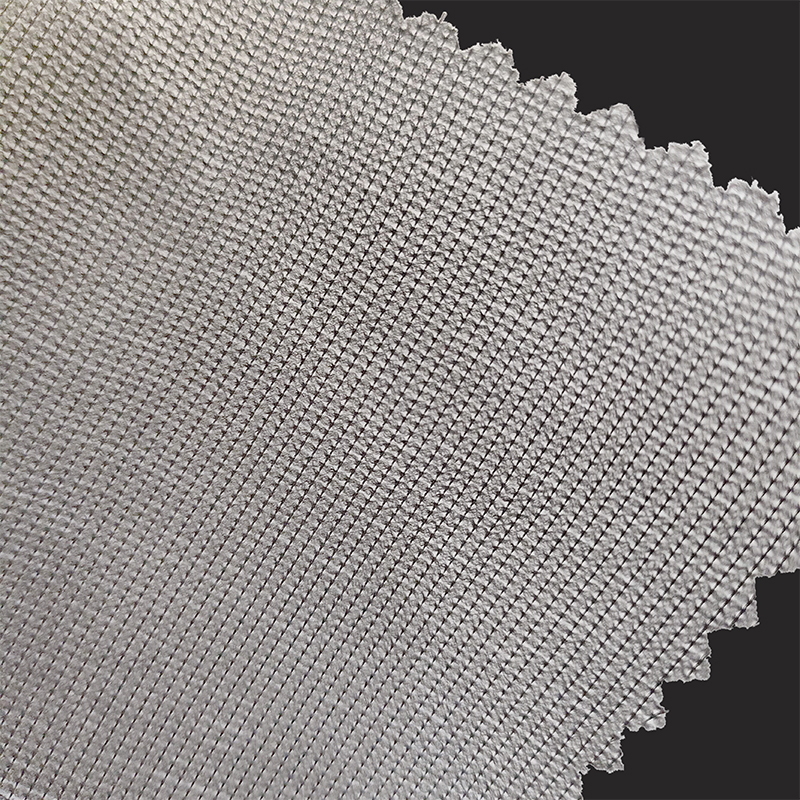

Breathability: Its mesh structure ensures good breathability and is suitable for applications that require air circulation, such as sportswear and footwear.

Fire resistance: Some products have fire resistance and can remain stable in high temperature environments, suitable for fields with high safety requirements.

3. Application fields

The wide application of double-sided adhesive film makes it an important material in many industries:

Textile industry: used for the fitting and decoration of clothing, it can effectively fix the fabric and improve the durability and aesthetics of the product.

Leather products: used in the production of handbags, shoes and other leather products to enhance the adhesion between materials and ensure the service life.

Foam materials: In the home, automotive and packaging industries, double-sided adhesive film can be used to fix and connect foam, providing excellent support and protection.

4. Convenience of operation

The use of double-sided adhesive film is very convenient. Only a simple pressing operation is required to complete the bonding, avoiding the complexity of traditional bonding methods. This feature makes it more efficient on the production line and reduces labor costs and time.

5. Market prospects

With the enhancement of environmental awareness and the advancement of material technology, double-sided adhesive film has great application potential in various fields. In the future, more companies will tend to use this environmentally friendly, economical and efficient material to meet market demand.

English

English Español

Español Türk

Türk